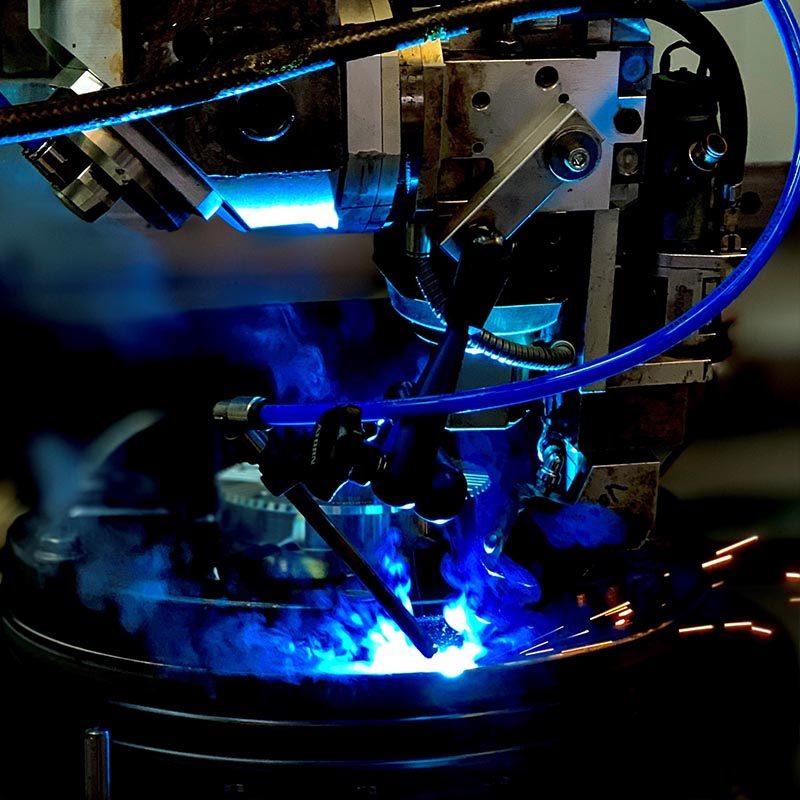

Laser welding

Laser welding is a highly modern, technologically leading and automated welding process for joining various metals and/or non-ferrous metals. BLS Lasertechnology GmbH supports customers with its long-standing and in-depth expertise in this laser technology.

What is laser welding?

Laser welding – also called laser beam welding / laser soldering- is per definition a welding process in EN ISO 4063 (“Process 52”). The process uses a laser for energy supply and applied for welding in a wide variety of industries. Generally, it requires no filler metal. However, some applications may use welding wire / filler wire or LMD powder depending on the requirements. Furthermore, different shielding gases support the process depending on the application and component.

Laser welding joins metallic as well as non-metallic materials. Possible are: Laser welding of aluminum, laser welding of stainless steel, laser welding of copper or laser welding of titanium. But BLS can also weld various special alloys or materials and reviews any special request.

We support you

Do you need help with the laser processing of your component? BLS is looking forward to helping you determine the requirements for your 3D laser material processing.

Due to the strong focus of the energy input, laser welding allows particularly deep and precise weld seams. The precision of the laser minimizes stress in the material and thus avoids distortion in the components. In addition, with a high welding speed and automation of the process, the technology offers efficient and fast processing of large quantities.

CNC-controlled 2D and 3D machines guide the laser along the component. In addition, for large-scale production series, complete automation of welding, including semi- or fully-automatic loading and unloading, is possible.

Laser welding is thus an ideal technology for precise, efficient joining of metallic materials and components. Due to its flexibility, the technology is suitable for prototypes, small, medium and large production batches. It supports a really wide set of interesting applications in a diverse set of industries.

Trust in over 30 years of experience.

With extensive laser experience, BLS supports customers as a contract manufacturer from parameter determination / basic development through prototype production to serial production. A high-performance machine park and different laser types enable an overall optimized service offering. The quality management system and exchange with leading research institutions ensure quality at the highest level.

You have questions about the service offering of BLS Lasertechnology GmbH?

Laser welding advantages

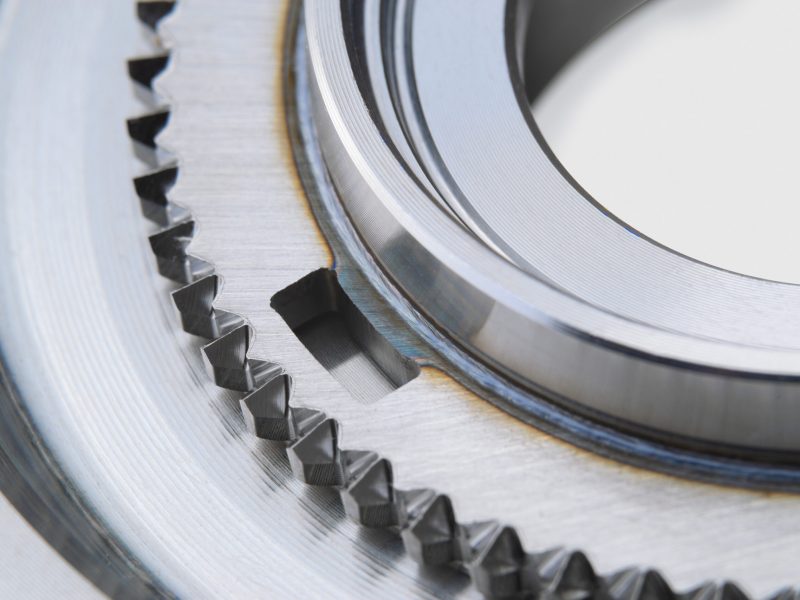

Joining components with laser welding offers extensive advantages. It can weld various materials and shapes / geometries. In addition to very high cost-effectiveness, it also consistently delivers highest quality. Due to the automated guidance of the laser, the precision of the process is second to none. This even allows to process components in a visible area.

- Accurate: spot welds up to a minimum diameter of approx. 0.5mm

- Precise: Machine and plant equipment with a repeatability of up to 0.01mm

- Powerful: welds with a welding depth of 0.5mm to 12mm

- Flexible: Extremely wide range of materials, complex material alloys on request

- Concentrated: Minimal thermal influence and thus low distortions and stress

- Efficient: Automated welding on CNC-controlled machines in the 2D and 3D range

- Versatile: All 2D and 3D geometries weldable and precise

- Repeatable: Robustly, reliably scalable via CNC automation, suitable for medium & large batches

Laser welding expertise

The high power and precision of a laser allows effective welding of a wide range of materials and geometries. Very common is laser welding of metal, laser welding of aluminum or laser welding of copper. Laser welding of titanium or laser welding of nickel is also possible.

Materials

- Metal: steel, stainless steel, mild steel

- Light metal: aluminum, titanium

- Non-ferrous metal: copper, nickel

- Castings and casting materials

- Special alloys, materials and plastics (e.g. black/white combinations, high-carbon steels) on request

Variants

- Laser welding with filler material (filler wire / welding rod, powder)

- Laser welding with shielding gas (nitrogen, oxygen, helium, argon and gas mixtures)

- Co2 or solid-state laser (YAG)

- Variable energy: <1KW to 12KW

- Pulsed or constant

Geometries

- All 2D & 3D geometries

- Sheet metal, thin sheet metal & other surfaces

- Lines and pipes

- Spatial geometries

- Large areas such as the welding of tailored blanks (sheet metal blank)

- Weld length (butt joint) up to 2.5M (single sheet width up to 1.3M x 2M)

- Special sizes upon request

BLS laser welding offering

BLS is an expert in laser welding in Germany and offers customers a wide range of services. In addition to laser welding contract manufacturing, the offer includes in-depth consulting, from the product development process (PEP) to sample production / prototype production to serial production

- Support in the design of the component for an optimal laser welding result

- Design and manufacturing of individual, customer-specific fixtures and clamping systems

- Cleaning of the metallic components with an in-house industrial cleaning plant

- Laser welding from prototypes (sample prototype production) to serial production

- (Partial) automation of loading and unloading for welding large batch sizes

- Determination of optimal laser types, parameter determination and application development

- Possibility to tack components manually before the automated welding process

- Heating: thermal with industrial furnace (internal dimensions: 1000 x 1000 x 1000mm), or inductive with generator

- 2D and 3D laser welding precise and accurate according to technical drawing

- Metallographic examination, micrographs with 160x magnification, Zeiss 3D measuring system, hardness testing

Welded joints & welds

BLS Lasertechnology GmbH masters all welding joints and weld seams. In addition, BLS helps to select the right type of welding for a component, depending on the material and application.

BLS can implement all types of joints after testing, such as:

- Laser welding with lap joint

- Laser welding with butt joint

- Laser welding with corner joint

BLS can implement all types of seams, such as:

- Laser welding with fillet weld

- Laser welding with I-seam

- Laser welding with spot weld

Laser welding procedures

BLS Lasertechnology GmbH can apply all common laser welding methods. In addition, BLS advises on the selection of the right method, taking into account the requirements of the weld seam and the component to be processed. Quality is always of highest priority.

Spot welding

Welding with temporally interrupted, single laser pulses; possible in different frequencies, energy levels & pulse durations

Seam welding

Continuous excitation of the active medium by processing with an uninterrupted laser beam

Deep welding

Particularly deep, uniform welds with the help of high laser power densities and a steam capillary

Scanner welding

Guidance of the laser beam via movable mirrors to weld processing fields in series quickly and precisely

Heat conduction welding

Joining of thin-walled parts with low material thickness by melting the materials at the joint by laser

Laser soldering

Alternative to manual soldering: joining materials with the aid of a soldering material