3D laser cutting

3D laser cutting is an effective and highly efficient process for cutting through various materials and substances. BLS Lasertechnology GmbH offers its customers in-depth expertise in this cutting technology – especially with regard to complex laser cuts with critical tolerances and in the 3D range.

What is laser cutting?

Laser cutting – also known as laser beam cutting – is a non-contact process for cutting metallic and non-metallic components. It uses a laser to remove the material by ablation. The laser heats the component surface to such an extent that a plasma is created and the material sublimates or vaporizes. Underlying / adjacent material layers stay undamaged.

A laser can cut almost all materials. The main scope of BLS services includes: aluminum laser cutting, laser steel cutting and sheet metal laser cutting. Our lasers can usually also cut various alloys and special materials, but our experts will validate the ability to process such parts in advance. In principle, even laser cutting of plastic or wood is possible.

We support you

Do you need help with the laser processing of your component? BLS is looking forward to helping you determine the requirements for your 3D laser material processing.

The flexibility and power of a laser allows to cut various material thicknesses extremely precisely, with minimal force and tight tolerances.

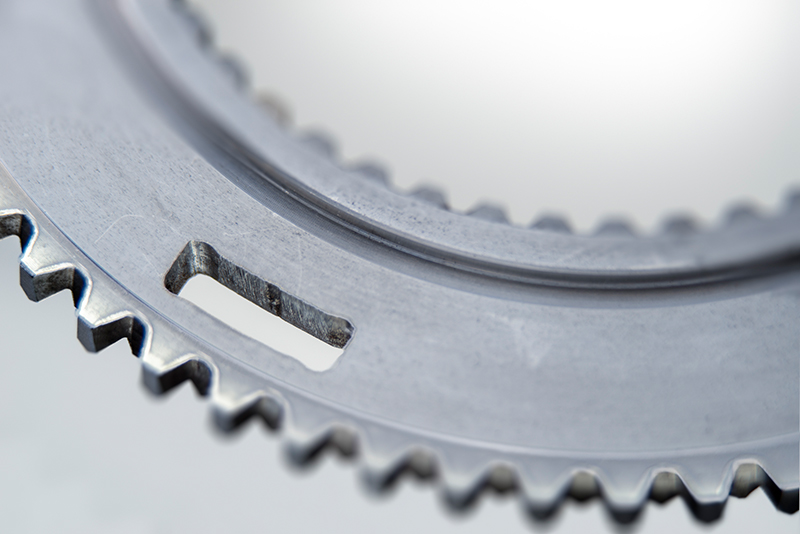

While other technologies apply enormous forces to parts, laser cutting generally avoids deformation, distortions or other defects. Due to the high accuracy, 3D laser cutting can even cut complex geometries with difficult-to-access areas.

The automated guidance of the laser enables an economic and highly efficient production of small and large quantities. In addition, there is only minimal waste compared to alternative cutting methods such as punching or nibbling. For large-scale production, BLS can also (partially) automate loading and unloading as required. The technology thus offers the ideal properties for efficient cutting of complex jobs.

Trust in over 30 years of experience.

With extensive laser experience, BLS supports customers as a contract manufacturer from parameter determination / basic development through prototype production to serial production. A high-performance machine park and different laser types enable an overall optimized service offering. The quality management system and exchange with leading research institutions ensure quality at the highest level.

You have questions about the service offering of BLS Lasertechnology GmbH?

Laser cutting advantages

Laser cutting brings a multitude of advantages for material processing. In addition to the usual metal laser cutting or sheet metal laser cutting, the process can cut a large variety of different materials and component geometries. The automated guidance, high accuracy and high process speed of the laser drive minimal waste and ensure high efficiency as well as low costs.

- Accurate: spot welds up to a minimum diameter of approx. 0.5mm

- Precise: Machine and equipment with a repeatability of up to 0.01mm

- Powerful: material thicknesses from 0.3mm to 10mm, depending on the alloy

- Contactless: No abrasion or wear, penetration of the material by heat exposure

- Efficient: Automated welding on NC-controlled machines in the 2D and 3D range

- Burr-free: all 2D and 3D contours can be cut without burr in the best possible way

- Repeatable: Robust and safely scalable through CNC automation

Laser cutting expertise

The laser cutting process can process a wide variety of materials and special substances. These include: Laser cutting of metal (in particular stainless steel laser cutting), aluminum laser cutting (alu laser cutting) and laser cutting of special alloys. 3D laser cutting also enables the cutting of any component geometry.

Materials

- Metal: steel, stainless steel, mild steel

- Light metal: aluminum, titanium

- Non-ferrous metal: copper, nickel

- Special alloys, special materials and plastics on request

- Other materials like glass and wood on request

Variants

- Flame cutting with oxygen

- Fusion cutting with nitrogen or argon

- Sublimation cutting

- Co2 or solid-state laser (YAG)

- Variable energy: up to 5KW

Geometries

- Sheet metal, thin sheet metal and other surfaces

- Large surfaces

- Lines and pipes

- Spatial geometries

- All 3D geometries cuttable & reproducible depending on accessibility

BLS laser cutting offering

BLS has a deep expertise in 3D laser cutting in Germany and offers customers a wide range of services. As a laser cutting service provider and contract manufacturer, BLS already helps with the design of the component to enable an optimal cutting result. In addition, an in-house measurement laboratory ensures highest quality.

- Support and help in the design of the component for an optimal cutting result

- Design and manufacturing of fixtures and clamping systems for precise cutting

- Cleaning of the parts before processing with an in-house industrial cleaning plant

- Laser cutting from prototypes (sample production) to serial production

- (Partial) automation of loading and unloading in large-scale productions

- Determination of optimal laser types, parameter determination & application development

- 3D laser cutting according to technical drawing and joint discussion of requirements

- Dimensional inspection of cutting geometries and cutting results with our own 3D Zeiss CMM measuring machine

Laser cutting Procedures

Three processes have become established in laser cutting: Flame cutting, fusion cutting and sublimation cutting. The difference between these cutting processes exists in particular with regard to the use of the cutting gas. BLS supports you in selecting the right process according to your requirements for the cutting process and the required cutting edges on the component.

Flame cutting

Use of oxygen as cutting gas, for cutting with high cutting speeds and thick materials

Fusion cutting

Use of nitrogen or argon as cutting gas, for virtually oxide-free cutting edges and minimal burr formation

Sublimation cutting

Beam evaporates alone, especially for fine, oxide-free cut edges with tight tolerances & complex contours