Best quality in laser processing

Quality in laser processing is a central component of the BLS corporate philosophy. The quality management system – certified according to ISO 9001 – aims at constant compliance with the highest quality standards and first-class results in laser material processing.

Quality in laser material

processing

Long-standing partnerships with renowned research institutions as well as cooperation with institutes in a number of committees ensure that BLS, as a technological leader, continues to offer its customers state-of-the-art laser technology.

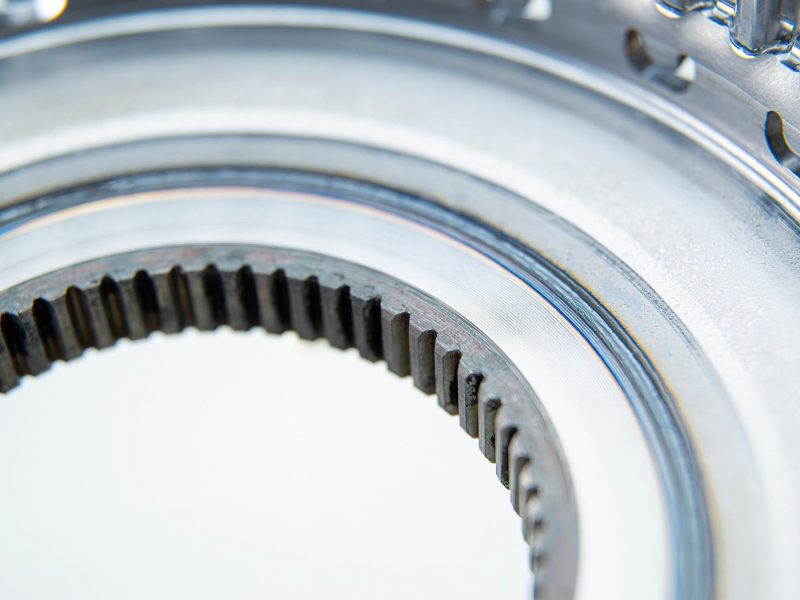

An in-house measuring laboratory with metallography lab, 3D-Zeiss measuring system as well as many other measuring instruments enable all critical quality controls for laser welding, laser cutting, laser hardening and laser metal deposition.

Automotive quality standards, such as sampling of series components according to the Production Part Approval Process (PPAP), are part of BLS’s standard operating procedures.

Certified quality management

Quality assurance is a top priority at BLS Lasertechnology. Standardized QM processes ensure compliance with the highest standards in laser material processing. Customer concerns and specifications are always taken into account and anchored in control and inspection plans. The quality management system is audited by independent institutions. BLS holds a DIN EN ISO 9001 certification.

- Dedicated quality management by certified International Welding Engineer (IWE/SFI) to ensure highest quality in laser processing

- Sampling of series components according to Production Part Approval Process (PPAP) and/or VDA standard

- Alignment on control and inspection plans (including control plan according to PPAP) with customers

- DEKRA certification of the quality management system according to DIN EN ISO 9001 and the environmental management system according to DIN ISO EN 14001

- Certification as an environmentally conscious company in accordance with the Peak Compensation and Efficiency System Ordinance

- Focus on constant optimization of all manufacturing and maintenance processes

Download of the quality certificates

Research partners and universities

BLS is in constant exchange with leading research institutions for laser welding, laser metal deposition and other laser processes such as 3D laser cutting and laser hardening. In this context, a large number of research and development projects are supported with know-how and in-depth laser expertise. To this end, BLS works closely with institutes in a number of committees. Through exchanges with leading research institutes and laser centers, BLS learns about the latest innovations first-hand.

In-house measurement laboratory

With a fully equipped, modern and in-house laboratory, BLS ensures best quality during serial production. The laboratory is a central part of the laser technology factory near Stuttgart, Germany, and is firmly integrated into daily production. The latest testing and measuring equipment technologies enable in-depth testing of laser processing results.

- Metallography lab for checking the results of laser processing, especially checking seam depth, bonding, root expression, microstructure, etc.

- Creation and documentation of micrographs with up to 160x magnification

- Zeiss 3D coordinate measuring machine for geometric measurement after 3D laser cutting, laser cladding or laser welding

- Hardness measuring system for checking the achieved metal hardness after laser hardening, laser welding or laser metal deposition

- Strict maintenance intervals of the laboratory equipment by BLS specialist personnel or the manufacturer's service department