Laser processing

with Trumpf laser

BLS relies entirely on Trumpf lasers for laser processing. Trumpf, as the market & technology leader in laser technology, has been an extremely close partner to BLS since its inception. The Trumpf laser processing centers at BLS consist of CO2 laser and solid state laser (YAG laser). In addition, BLS has a fixture and equipment manufacturing facility, a Dürr/ Ecoclean industrial cleaning facility, industrial furnace, joining equipment / presses, and a measurement laboratory.

Quality of Trumpf in laser material processing

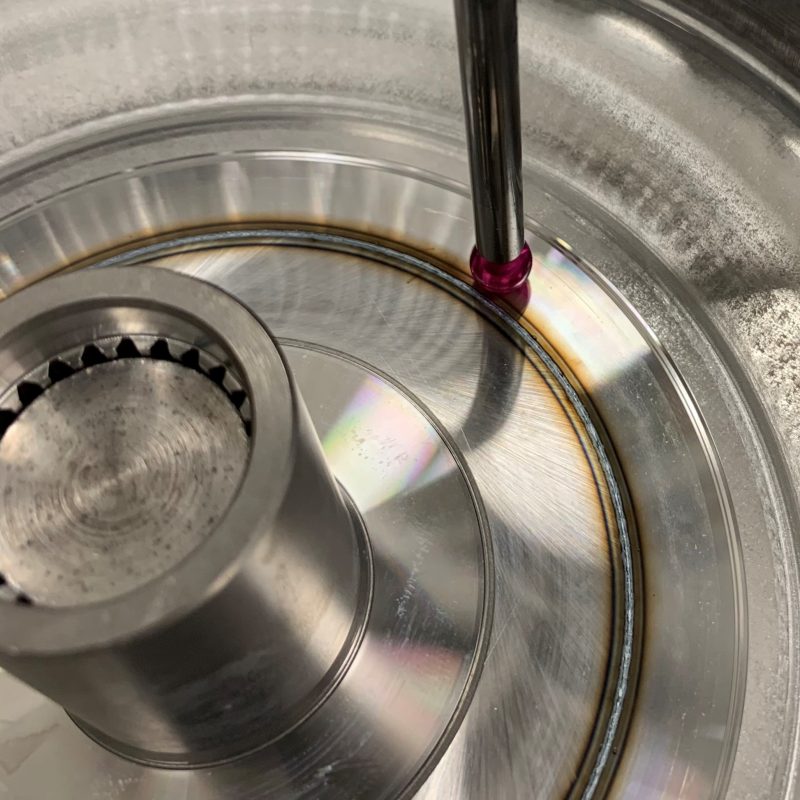

The Trumpf laser systems from BLS Lasertechnology GmbH enable the best quality in 3D laser processing. In addition to laser welding and laser metal deposition, BLS can also use the lasers flexibly for 3D laser cutting and laser hardening.

The BLS machine park covers a wide range of different lasers for material and surface treatment of metal and other materials. CO2 lasers with a laser power of up to 8KW and YAG lasers (solid state lasers) with a laser power of up to 6KW are available. In addition, there is a Trumpf laser system for NC laser applications in the thin sheet area and different tacking and fixing work as well as Trumpf scanner optics for remote welding and cutting (Programmable Focusing Optics, PFO).

The BLS laser processing centers with 5 axes and an additional rotary axis allow the machining of extremely extensive geometries and shapes. A working range of up to 3M x 1.5M x 0.75M with a maximum outer diameter of 1.5M is available as standard, further dimensions are possible on request after checking the requirements.

We support you

Need help selecting the right type of laser for processing your part? BLS will be happy to help you determine the requirements for your 3D laser processing

In addition to the Trumpf laser systems, BLS has other extensive equipment for laser processing of metal components. This ensures an optimal overall result for laser welding and other laser processes.

In our own workshop, individual joining systems and presses, testing equipment using light-sectioning technology, testing systems for leak testing, and various automations and special systems can be built according to individual requirements.

An in-house Dürr / Ecoclean cleaning system can optimally prepare components for laser material processing. In addition, an industrial furnace (internal dimensions: 1000 x 1000 x 1000mm) for thermal heating up to 550°C and a generator for inductive heating of the components before laser processing are available.

For quality assurance, BLS has its own measuring laboratory with metallography lab and Zeiss CMM measuring machine for continuous quality control during laser production.

3 Trumpf CO2 (TLC1000/1005) laser processing centers

- 5 axes & 1 rotary axis each

- Up to 8KW

- Programmable focusing optics (PFO) & scanner optics (e.g. for laser welding of non-ferrous metals)

- Working range: 3000mm x 1500mm x 750mm

- B: +/- 120°

- C: n x 360°

- A: Ø max. 1500mm

Trumpf YAG / solid state laser processing center

- 5 axes & 1 rotary axis

- Up to 6KW

- Programmable focusing optics (PFO) & scanner optics (e.g. for laser welding of non-ferrous metals)

- Working range: 3000mm x 1500mm x 750mm

- B: +/- 120°

- C: n x 360°

- A: Ø max. 1500mm

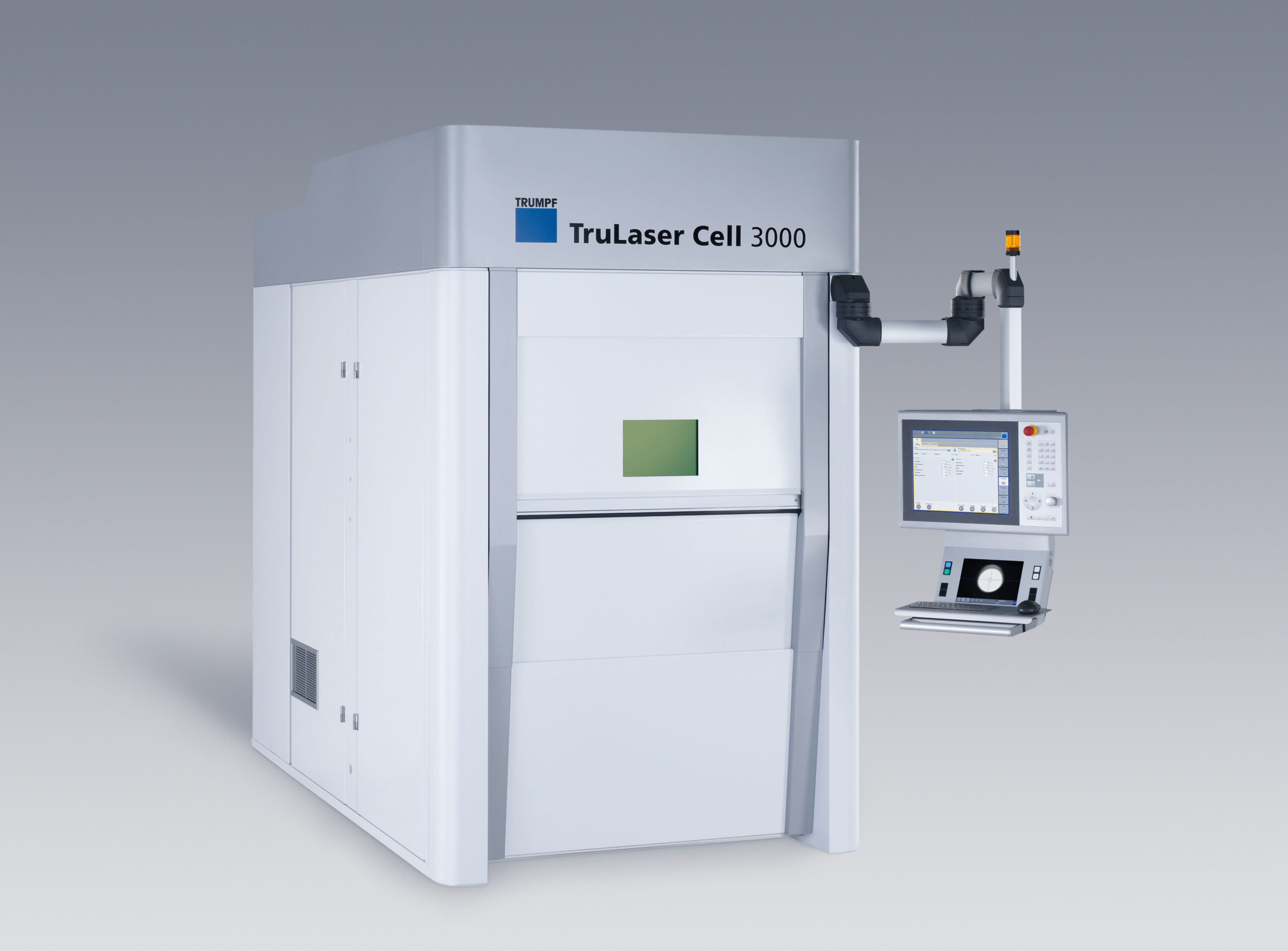

Trumpf TruLaser Cell 3000 (YAG / solid state)

- 5 axes & 1 rotary axis

- Up to 6KW

- Integrated camera system

- Working range: 800mm x 600mm x 400mm

- B: +/- 120°

- C: n x 360°

- A: Ø max. 600mm

Trumpf Station 5010

(YAG / solid state)

- 3 axes & 1 rotary axis

- Up to 0,5 KW

- Integriertes camera system

- Working range: 1000mm x 1000mm x 1000mm

- B: +/- 120°

- C: n x 360°

- A: Ø max. 60mm

Trumpf PFO

- Trumpf programmable focusing optics (PFO)

- Scanner optics for remote welding and cutting

- Predestined for welding of non-ferrous metals (including Cu)

Rohde industrial furnace & induction heating

- Thermal heating of components with Rohde industrial furnace

- Furnace with capacity of 1000mm x 1000mm x 1000mm

- Inductive heating via generator also possible

TruMark Station 5000

- With trumarking laser TruMark 6030

- Precise marking, engraving and coding of components

- Traceability of components (e.B. with Data Matrix Codes)

- Possibility of ablation and laser cleaning

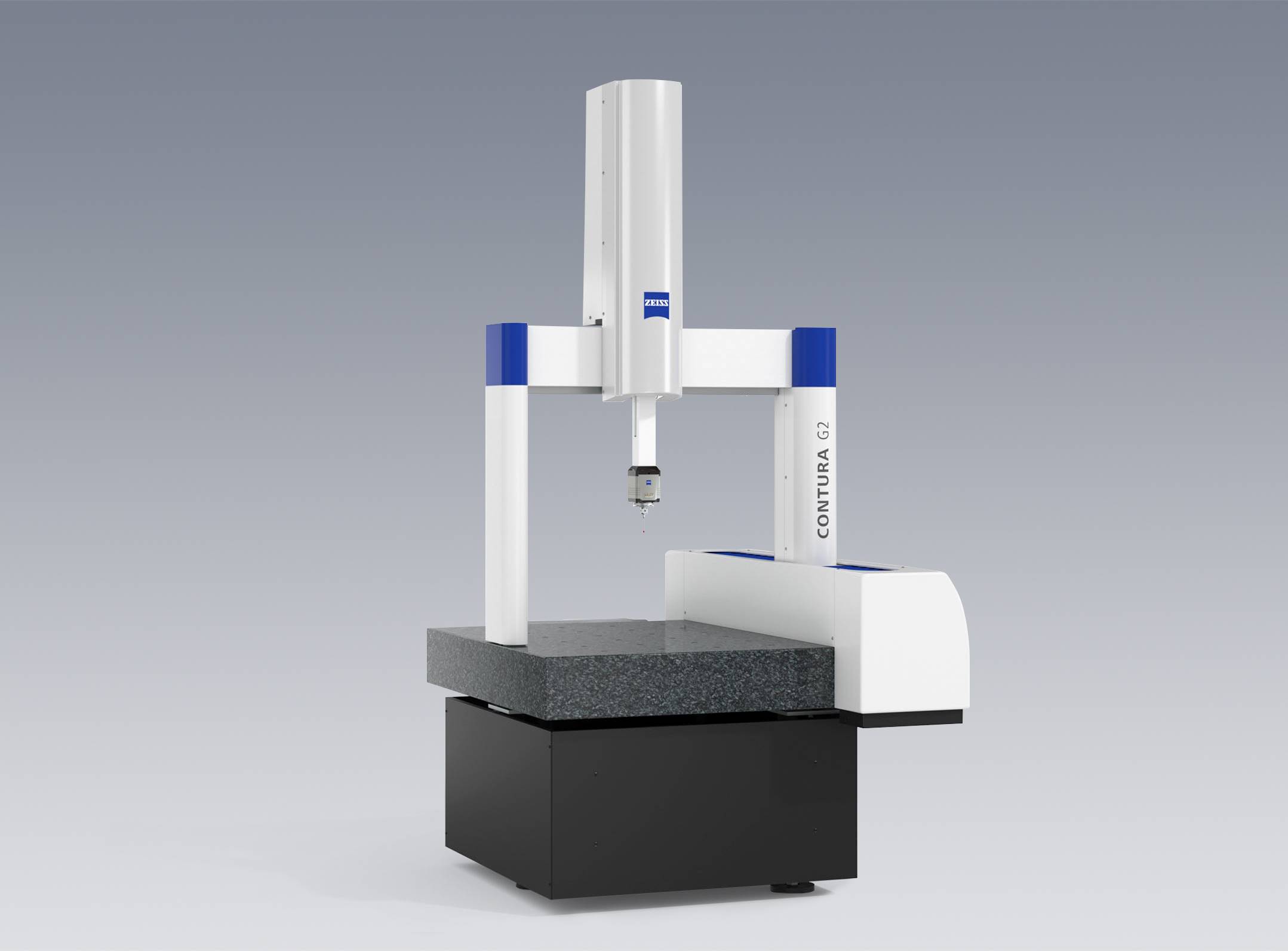

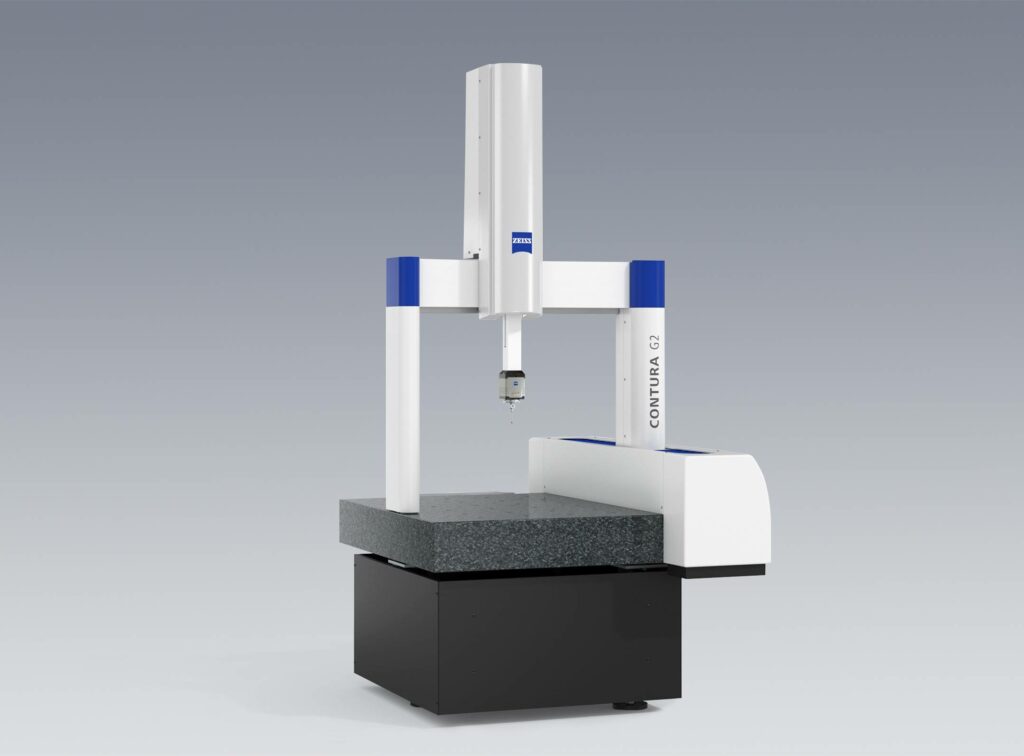

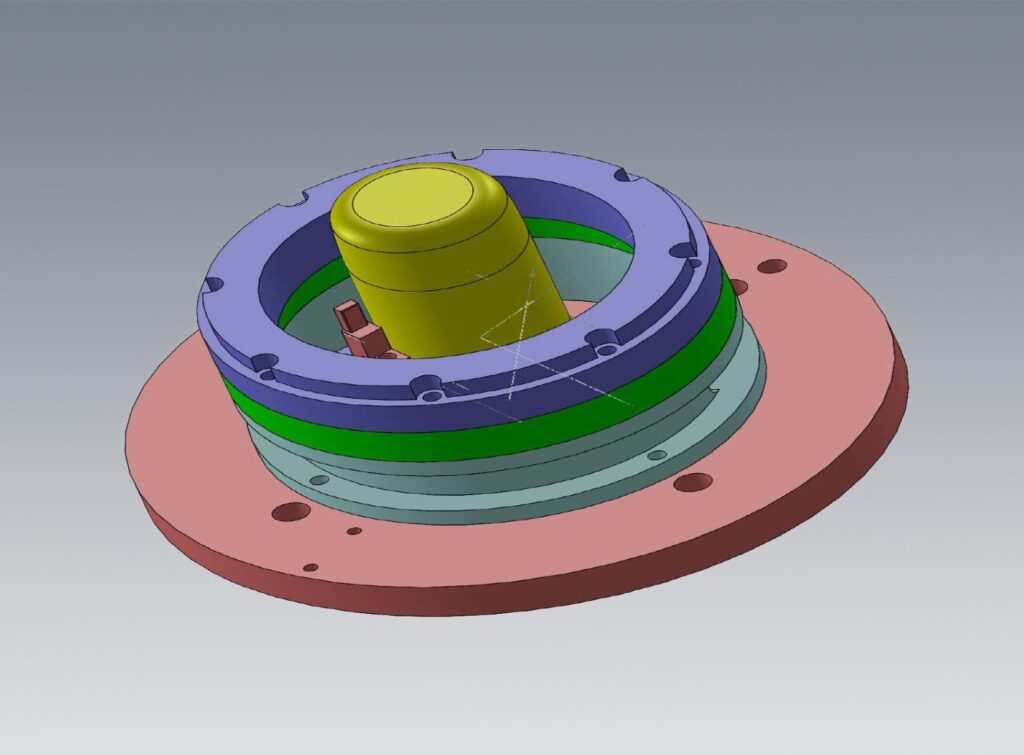

Zeiss CMM (Contura G2) & metallography lab

- Zeiss Coordinate Measurement Machine with ceramic guideways and air bearings

- Microscope with 160x magnification for metal micrographs

- Hardness measuring system

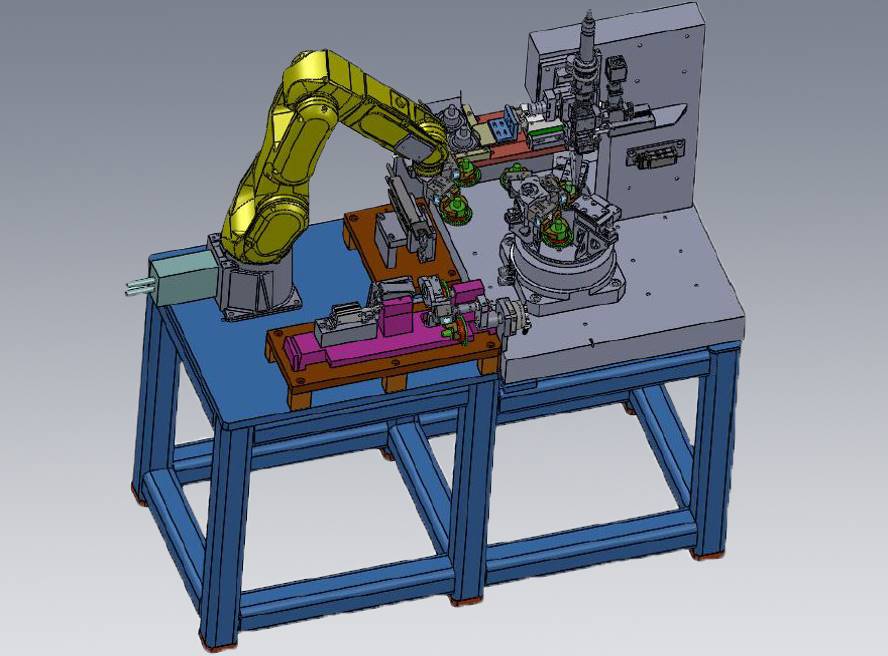

Customer-specific joining, testing & welding equipment

- Among other things, fully automatic joining systems, testing systems, leak testing equipment

- Fully automatic 100% inspection with e.g. light-sectioning method or leak tests

Dürr / Ecoclean cleaning system

The cleaning of components before processing with the laser is essential for the product quality and the process outcome. Dirt particles or preservatives are removed in advance. The Dürr / Ecoclean industrial cleaning system from BLS offers an excellent and environmentally friendly solution for cleaning the components.

- High capacity in terms of throughput and production volume to be cleaned

- Cleaning possible from quantity 1 (prototypes) up to series volume möglich

- High flexibility in size and shape of the components - even complex geometries

- Extremely environmentally friendly with a closed loop system and use of ultrasound

- Cleaning of various metals before and / or after processing with the laser

In-house measurement laboratory

With an extensively equipped, modern and in-house laboratory, BLS ensures best quality during serial production. The laboratory is a central part of the laser technology factory near Stuttgart, Germany, and is firmly integrated into daily production. The latest testing and measuring equipment technologies enable in-depth testing of laser processing.

- Metallography lab for checking the results of laser processing, especially checking seam depth, bonding, root expression, microstructure, etc

- Creation and documentation of micrographs with up to 160x magnification

- Zeiss 3D coordinate measuring machine for geometric measurement after 3D laser cutting, laser cladding or laser welding

- Hardness measuring system for checking the achieved metal hardness after laser hardening, laser welding or laser metal deposition

- Strict maintenance intervals of the laboratory equipment by BLS specialist personnel or the manufacturer's service department

Fixture and plant construction

In the production near Stuttgart, Germany, BLS Lasertechnology GmbH has its own mechanical workshop in addition to the classic laser equipment park. Here, BLS manufactures customer- and component-specific fixtures as well as joining and testing systems according to individual requirements. In addition to milling, turning, grinding, there is also the possibility of joining by means of arc processes (MIG/MAG).

- Construction of fixtures for dimensionally accurate fixing of components during laser processing of prototypes and series orders

- Design and construction of automatic equipment for laser welding of large-scale orders

- Fully automatic 100% testing systems, e.g., by means of light-sectioning, leak testing systems

- Further customized structures and fixtures can be made as requested after validating the requirements

- Depending on requirements and needs, we work together with selected tool and plant manufacturers as well as automation engineers