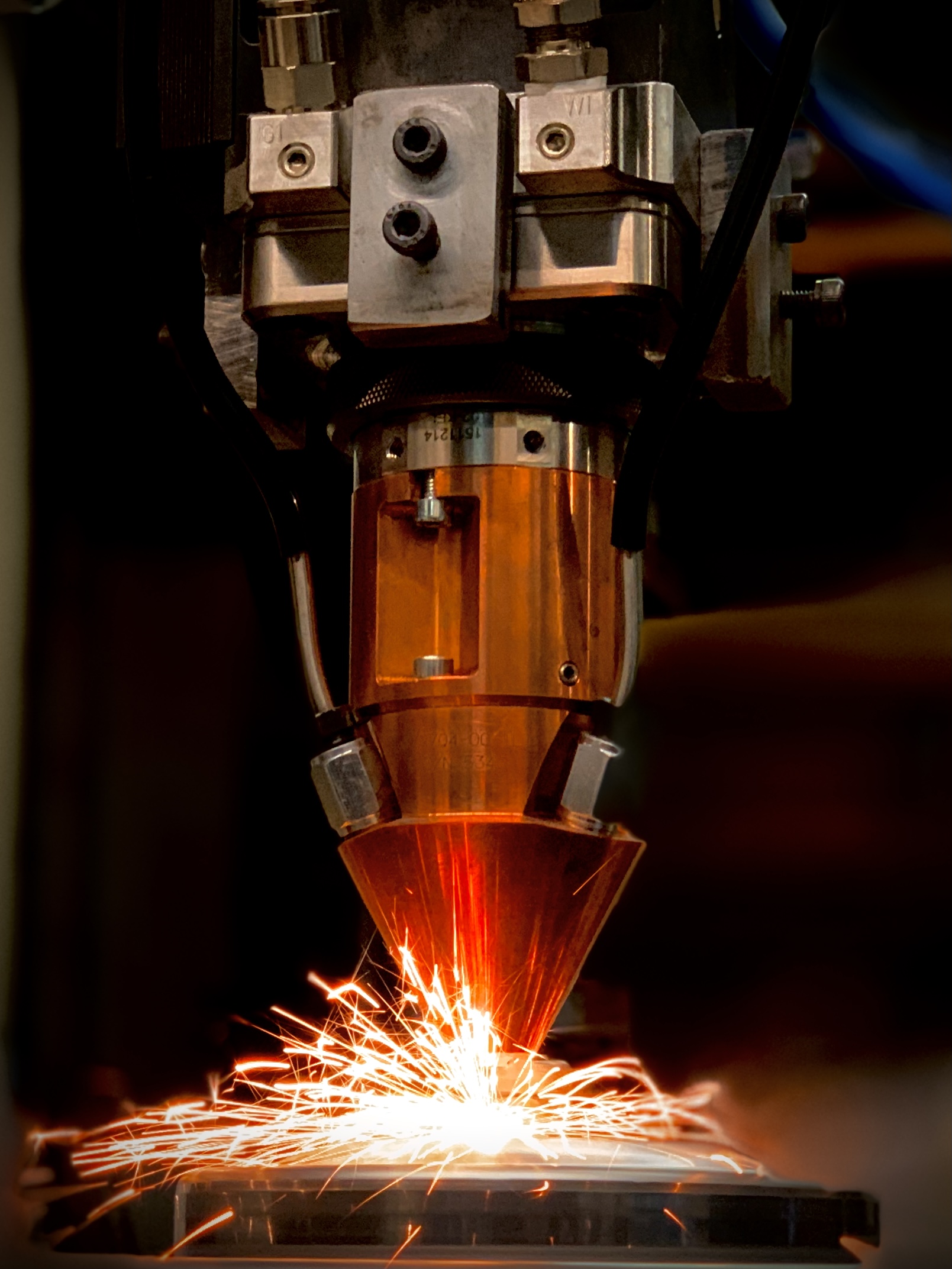

OVER 35 YEARS OF EXPERIENCE IN LASER MATERIAL PROCESSING

BLS Lasertechnology GmbH is a leading expert in laser material processing from Germany. The company helps customers from diverse industries with laser processing of metal components

Our customers:

Our research partners:

Overview of services

As a technology company, BLS is a long-standing partner to industry for complex and technologically demanding laser applications. BLS offers laser material processing at the highest level.

Laser welding

Extremely precise joining of metals or non-ferrous metals in the 3D range

Laser cutting

Effective and efficient cutting of various metallic materials in the 3D range

Laser metal deposition

Additive 3D laser process with special metallic powders (LMD, direct metal deposition)

Laser hardening

Targeted, precise and efficient hardening of metallic

components

Laser marking

Flexible, precise marking, engraving, coding, ablation and cleaning

Trust in over 35 years of experience.

MWith extensive laser experience, BLS supports customers as a contract manufacturer from parameter determination / basic development through prototype production to serial production. A high-performance machine park and different laser types enable an overall optimized service offering. The quality management system and exchange with leading research institutions ensure quality at the highest level.

You have questions about the service offering of BLS Lasertechnology GmbH?

Service range

BLS develops individual and customized solutions depending on the requirements of its customers

Lot

sizes

Prototypes (batch size 1) up to automated serial production(up to 1 million parts p.a.)

Fixture construction

Design manufacture of fixtures for prototypes and serial productions through in-house fixture construction

Quality

assurance

Fully equipped lab with Zeiss 3D system, own metallography lab, hardness measuring & other devices

Many customers from various industries rely on the laser expertise of BLS

With over 14,000 laser beam-on hours p.a. and more than 400 customers, BLS Lasertechnology GmbH is an experienced partner to many industry-leading companies

Unsere Produktionsstätte

Proin gravida nibh vel velit auctor aliquet aenean sollicitudin, lorem quis bibendum auctor nisi elit consequat ipsum.

Laser applications

at the highest level

BLS Lasertechnology GmbH stands for

- High laser expertise and innovative power

- Close cooperation already in the product development process

- Process development and parameter determination

- A wide equipment range and high performance laser systems

- Quality as a corporate philosophy

- Outstanding problem-solving competence