Services

BLS offers customers four procedures for laser processing of metal components. Laser welding for joining two or more components, laser metal deposition (LMD) for applying a metallic additive, 3D laser cutting and laser hardening of a component.

Overview of Services

As a technology company, BLS is a long-standing partner to industry for complex and technologically demanding laser applications. BLS offers laser material processing at the highest level.

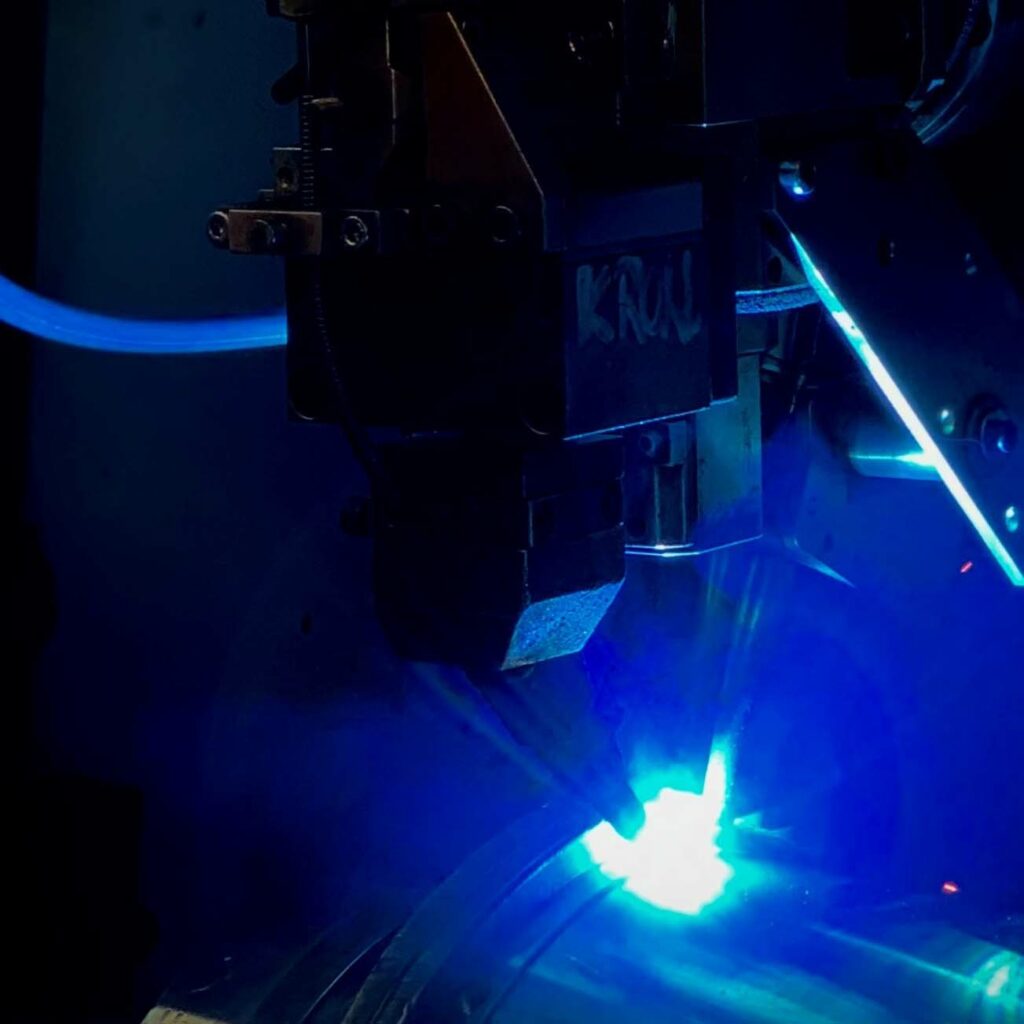

Laser welding

Extremely precise joining of metals or non-ferrous metals in the 3D range

Laser cutting

Effective and efficient cutting of various metallic materials in the 3D range

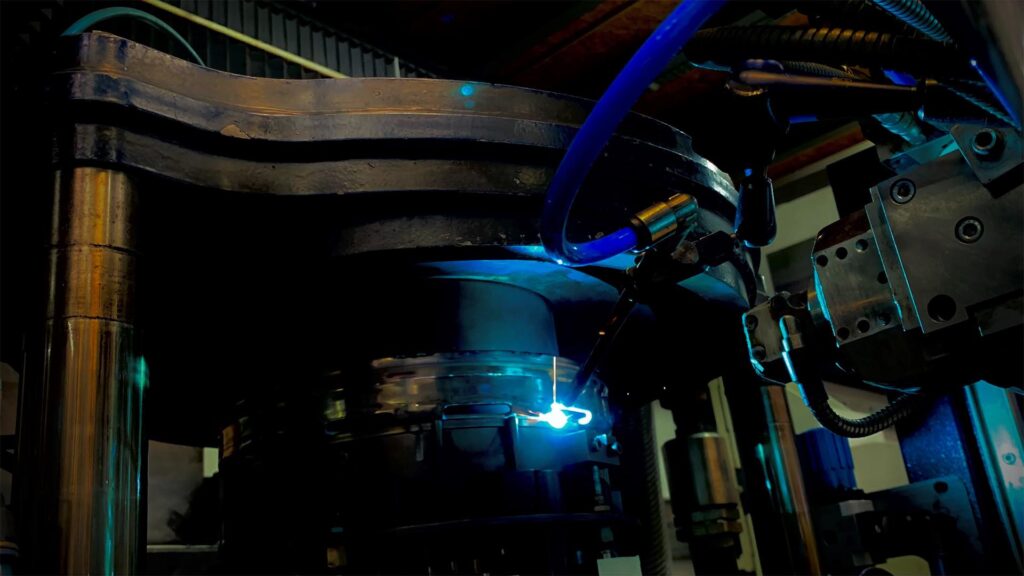

Laser metal deposition

Additive 3D laser process with special metallic powders (LMD, direct metal deposition)

Laser hardening

Targeted, precise and efficient hardening of metallic components

Laser marking

Flexible, precise marking, engraving, coding, ablation and cleaning

Trust in over 30 years of experience.

With extensive laser experience, BLS supports customers as a laser contract manufacturer from parameter determination / basic development through prototype production to serial production. A high-performance machine park and different laser types enable an overall optimized service offering. The quality management system and exchange with leading research institutions ensure quality at the highest level.

You have questions about the service offering of BLS Lasertechnology GmbH?

Laser welding

Laser welding is a highly advanced, technologically leading and automated welding process for joining various metals and/or non-ferrous metals. Laser welding of components offers many advantages over alternative welding methods:

- Highest precision and quality due to CNC-controlled guidance of the laser

- High efficiency due to automation of the welding process

- Use with a wide variety of materials and alloys

- Machining of various 2D and 3D geometries without limitation

- Minimal distortion due to extremely low thermal influence

Laser cutting

Laser cutting is an extremely efficient process for cutting through various metal parts. BLS helps customers especially with complex laser cuts with critical tolerances and in the 3D range. Advantages of laser cutting are in particular:

- High efficiency due to extremely high process speeds

- Highest precision and quality due to CNC-controlled guidance of the laser

- Wide variety of materials and alloys that can be cut

- Cutting 2D and 3D contours without restriction

- No material abrasion or wear due to non-contact cutting via heat impact

Laser metal deposition (LMD)

Laser metal deposition (LMD) is an innovative, additive laser process for modifying metal components. BLS supports the application of this modern technology, e.g. for the repair of high-quality components or concentrated reinforcement for protection against wear and tear

- Selective and efficient use of high-priced materials and substances

- Highest precision and quality due to CNC-controlled guidance of the laser

- Fast processing of parts due to very high application rates and automated laser guidance

- Can be flexibly combined with laser welding and laser cutting

- Minimal distortion and no burn-in spots or pores due to low heat input

Laser hardening

Laser hardening enables fast and concentrated hardening of metal components. The process offers high efficiency and high flexibility:

- Complex contours and shapes of a component achievable with the laser

- Maximum possible hardness values depending on the martensite formation of the material

- Highest accuracy and quality through CNC-controlled, automated laser guidance

- Minimal distortion due to extremely low heat input into the component

- Low costs due to short cycle times and high process speeds

Laser marking

Laser marking is a versatile process that can label, engrave or apply specific codes (such as Data Matrix codes) to components by laser.

Marking components with lasers offers extensive advantages over conventional marking processes based on paint, chemical reaction or mechanical pressure:

- Environmentally friendly: without costly and environmentally harmful consumables

- Gentle on material: hardly any tool or material wear

- Permanently readable: good readability with high chemical and thermal resistance

- Energy saving: requires little energy

- Fast: process speeds from 6 to 150 cm/min

- Easy individualization of components: e.g. via Data Matrix Code

- Reliable traceability over the entire life cycle

What our business partners are saying about us

BLS Lasertechnology as laser contract manufacturer maintains close, trusting and long-term relationships with suppliers and customers

“BLS’s expertise in laser material processing is extremely rare. There are probably less than 5 companies that offer similar laser know-how.”

Sales manager of a

leading supplier of lasers and

laser technology

“Over 30 years experience

in laser processing make BLS one of the leading company and experts in our industry”

Division manager at an international Tier 1 automotive supplier

“BLS is one of our A suppliers and convinces us again and again with its high quality and customer orientation”.