Laser processing for

commercial vehicles and agricultural machinery

With a large number of implemented projects, BLS Lasertechnology GmbH is a seasoned and trusted partner for laser processing of commercial vehichle and agricultural machinery parts.

BLS offering for customers from the

commercial vehicle industry

A high-performance machine park and different types of lasers and systems enable an overall technologically optimized service offering for automotive customers. Certifications (including ISO 9001) and decades of experience of BLS experts in the field of laser technology ensure quality at the highest level.

BLS can weld, clad (LMD, laser deposition welding), harden or cut countless material pairings and a wide variety of components for use in the commercial vehicles and agricultural machinery. BLS customers receive competent support from parameter determination and basic development, through prototype orders, to serial production orders. BLS offers also the implementation of specific requirements as well as the design and construction of cycle time-optimized clamping fixtures.

Laser material processing of

parts in commercial vehicles &

l agricultural machinery

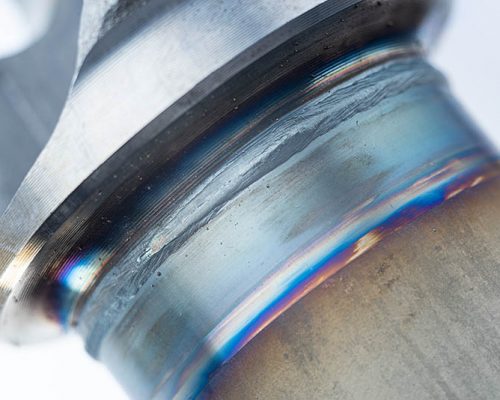

BLS Lasertechnology GmbH enjoys the trust of a large number of manufacturers and suppliers in the commercial vehicle sector for laser material processing of components. This includes laser welding, laser cutting, laser metal deposition and laser hardening of components. In particular, laser metal deposition (LMD) for wear reduction is of great importance for commercial vehicle parts, which have to withstand to high loads.

“Impressive expertise in laser welding”

Buyer for a leading manufacturer of commercial vehicle components

Examples of laser parts of commercial vehichles & agricultural machinery:

- Commercial vehicle tools, such as excavator buckets that can be protected from high wear & tear or repaired with laser metal deposition

- Special chassis elements such as roll bars, which must provide high stability and safety

- Elements of the power train, including engine parts, transmission parts and exhaust train components

- Functional parts such as hydraulic tubes, telescopic tubes and hydraulic rods for use in truck cranes

- Components of electric motors such as stators, rotors, rotor laminations, bearings, shafts and lubricant inlets

Our customers from the

sector for commercial vehicles and

agricultural machinery

A number of leading international companies trust BLS with the laser processing of commercial vehicle and agricultural machinery components. We look forward to many more technologically challenging projects that we can tackle with customers in this industry.

“The quality of BLS in laser welding is extraordinary. We consistently enjoy working with them”